Summary

If unbraided corrugated metal hose is subjected to high pressure, the hose is elongated beyond its recovery range.

Braids are necessary to equip the hose to prevent elongation under internal pressure.

To increase pressure resistance, metal hoses can be equipped with one or two-layer braiding.

The braiding is firmly connected to the hose fittings on both sides to absorb the longitudinal forces caused by internal pressure.

The braid acts to support the core against pressure and also provides a restraint to prevent the expansion of the length of the hose under internal pressure.

For higher pressure, multiple layers of braid are used to increase the pressure resistance of the hose assembly.

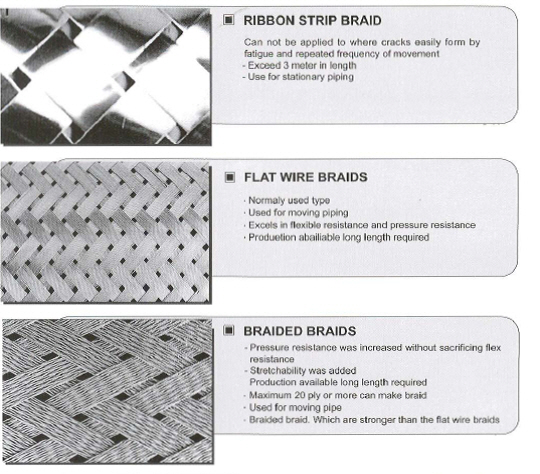

There are three types of braid pattern i.e. ribbon strip braid, flat wire braid and braided braids.

The braids are designed to be strong enough to withstand elongation for the pressure rating of the hose.

The braid material is usually similar to that of the hose with which it is used, but may be different for reasons of strength, corrosion resistance.