- Summary

-

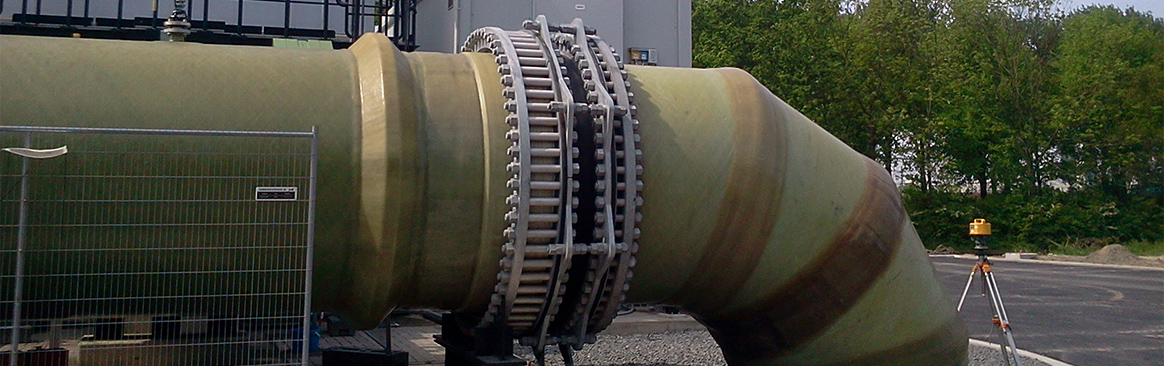

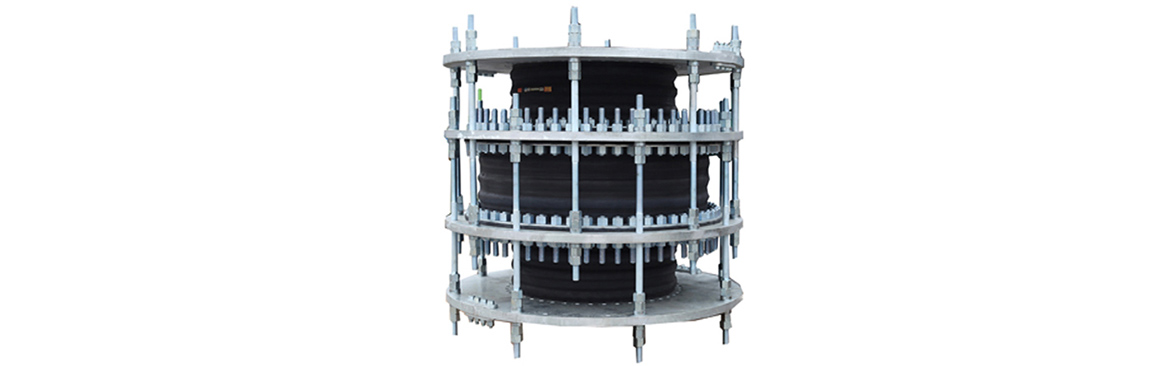

MEGAFLEXON rubber expansion joints have been specified and used for many years by consulting engineers, mechanical contractors, pressure vessel designers, plant engineers and turn-key construction firms.

They are installed to accommodate movement in piping runs, protect piping from expansion and contraction and insure efficient and economical on-stream operations. Rubber expansion joints are specifically engineered and designed section of pipe that is flanged and is able to be inserted within a rigid piping system with the goal to be the achievement of one or more of the following.Rubber expansion joints, designed by engineers and fabricated by skilled craftsmen, are used in all systems conveying fluids under pressure and or vacuum at various temperatu res, and advantages are as follows :

- MENU

- About

- Product

-

METAL EXPANSION JOINT

- MENU

- METAL EXPANSION JOINT

- BASIC DESIGN

- Single Type

- Universal Type

- Hinged Type

- Gimbal Type

- Rectangular Type

- SPECIAL DESIGN

- Pressure Balanced Type

- Thick Wall/Flanged & Flued Type

- Externally Pressurized Type

- Jacketed Type- Clamshell Type

- Clamshell Type

- Two-Ply Testable

- PTFE-lined Type

- High Pressure Type

- FCCU Expansion Joint

- Pantograph Type

- MENU

- RUBBER EXPANSION JOINT

- FABRIC EXPANSION JOINT

- FLEXIBLE METAL HOSE

- Quality

- Services

- News

- Gallery

- Catalogs