Summary

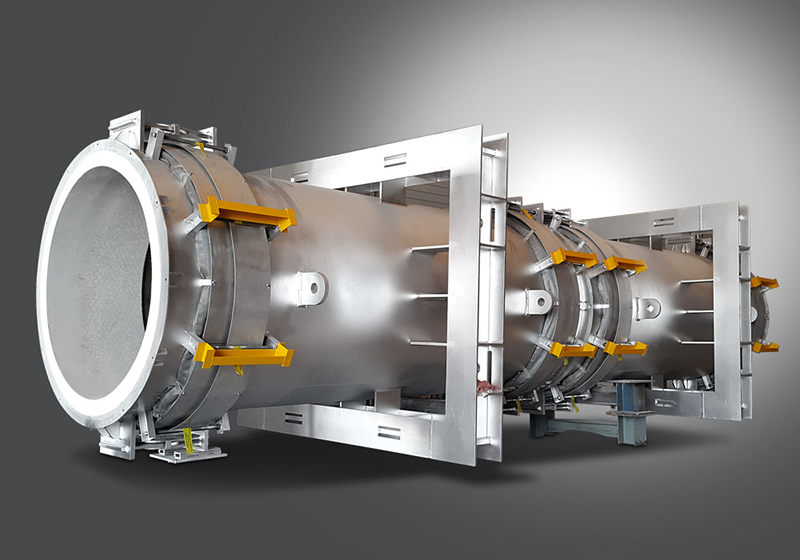

The types of expansion joints used in Fluid Catalytic Cracking Unit (FCCU) service are some of the most critical

expansion joints operated at high pressures, high temperatures, large movement and very aggressive fluid. FCCU expansion joints are customized and highly pre-engineered expansion joints.

The design of FCCU expansion joints is complex due to following reasons.

– to absorb large movements

– to operate at high temperature

– to resist erosion and acid dew point corrosion

– to need two-ply testable device to detect ply failure

We are designed in accordance with the following requirements.

– ASME B 31.3 Appendix X and EJMA Standards

– Licensor’s requirement such as UOP, KBR, Axens, ExxonMobil etc.

– Other Applicable Codes and Std.

FCCU expansion joints are typically tied universal, Gimbal, hinged and pressure balanced type and can be grouped in three major categories as hot wall, cold wall and unlined.

The cold wall design is refractory lined to ensure the shell temperature does not exceed the available value.

Also, an external insulation is applied to prevent the bellows from the acid dew point which is the main cause of bellows premature failure.

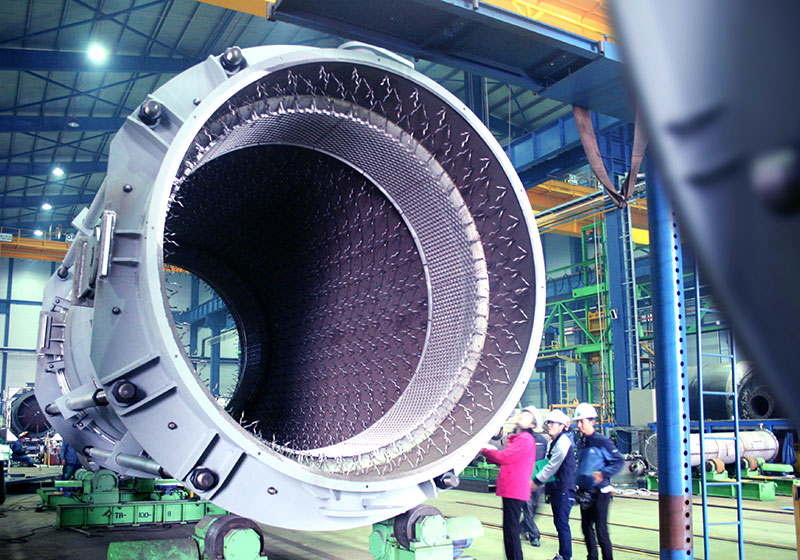

The hot wall design includes an abrasion resistant lining, hex-mesh and castable material or refractory.

The lining is not intended to be used as a thermal barrier and requires a specific and qualified drying process.